Development

-

STEP 01We provide customers with a complete customization solution, from initial product concept, market research ,design and production. The customers can be sure that the final product will exactly meet their needs and specifications, as well as being up to date and fitting the latest market trends.

-

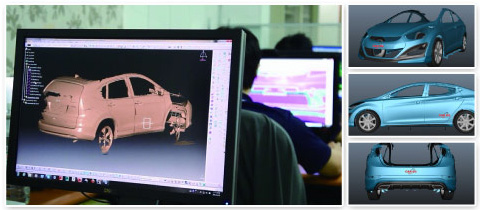

STEP 02From the initial sketches through the 2D and 3D design, the concept is continuously reviewed and revised until the design is finalized.

-

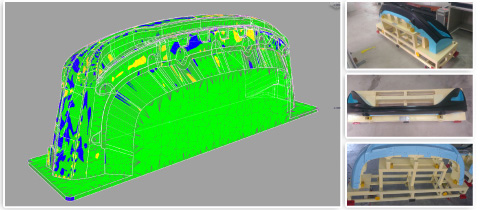

STEP 03A prototype is then produced which is fitted to ensure that the form and function meet all specifications. The mold is ready to build then.

-

STEP 04All mold are built by our highly trained staff and closely monitored to ensure that each step in the process is performed correctly ,CNC plays a major role.

-

STEP 05We have strict quality control inspections for each new mold. For example, to check the flatness of the mold surface we subject it to a close visual inspection by our trained engineers. Once we are satisfied, we scan it and then compare to the 3D data we obtain-ed earlier. Only if the data matches will the mold be accepted.

-

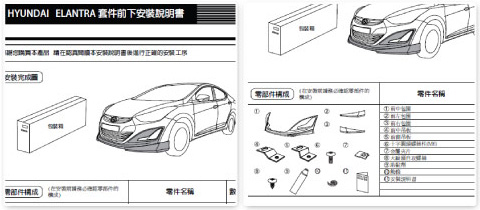

STEP 06Body kits are picked up from production randomly and installed to the specific model for Quality inspection and assurance.

-

STEP 07Installation guide printed.

-

STEP 08Manufacturing.